Stainless Steel in Fire

| Led by: | Peter Schaumann |

| Team: | Florian Kettner |

| Year: | 2005 |

| Funding: | RFCS (EU) |

| Duration: | 01.05.2005 - 30.06.2007 |

| Is Finished: | yes |

Project Summary

The RFSC-project (Contract No RFS-CR-04048) “Stainless Steel in Fire” seeks to develop more comprehensive and economic design guidance on structural stainless steel members and connections in fire. This includes specific unprotected products meeting the requirements for 30 and 60 minutes fire resistance. The project covers tests on materials, members and connections, numerical analysis and development of design guidance. The comprehensive final report will provide design guidance in a suitable format for inclusion in European standards, accompanied by web-based design software.

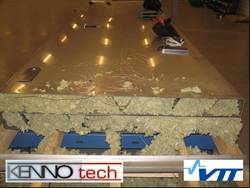

The Institute for Steel Construction is involved with numerical studies in investigations on a new type of laser-welded stainless steel sandwich panel developed by Kenno Tech Ltd., Finland. The sandwich panel consists of two stainless steel sheets as cover plates and V-profiles forming the web of the section, as shown in Fig. 1 and 2. The voids are filled with insulation material, e.g. rock wool, to improve the thermal behaviour. It is the aim of the study to prove that a fire resistance of 30 to 60 minutes can be achieved without additional active or passive fire protection.

The main structural benefit of this type of welded metal sandwich panels is a high strength to weight ratio, which means advantages for transport and installation at the building site. Previously, these types of structures have been made of carbon steel, but new welding techniques have made it possible to produce them also from stainless steel. The main applications for the sandwich panels are in transportation, ship building, construction industry and process industry, especially where the advantages of stainless steel (resistance to corrosion, increased strength in fire situation, sanitary applications, low maintenance costs) can be beneficial.

The investigation of WP 1 "Fire resistant stuctures and products" are performed in cooperation with VTT Technical Research Centre of Finland. Within this project the work in Hannover is concentrated on numerical studies. Therefore the insulated panel is modeled with ABAQUS/Standard.

The analysis is devided into a preliminary two dimensional thermal analysis as shown in Fig. 3 and an load bearing calculation with a three dimensional shell-model. The calculation follows three (optional four) steps:

- Linear buckling analysis to determin an imperfect geometry

- Application of imperfections and mechanical loads

- Heating of the stainless steel panel to either measured temperatures from the fire test or temperatures obtained from numerical calculation

- Optional: Load increasing until failure

An example for the results of the linear buckling analysis is shown in Fig. 4 for the buckling of the compression zones at the upper sheet at midspan and the lower sheet at the support.

Finally the imperfect geometry is loaded and heated by standard fire from below. This leads to deflections mainly governed thermal bowing.

Some of the KENNOtech-results have been published at the "Fourth International Workshop Structures in Fire" in May 2006. Here is a pdf-version of the paper.

Contractors

- Institute for Steel Construction, Leibniz University Hannover (Germany)

- .....