Lightweight Lattice Structures

International Collaborative Project

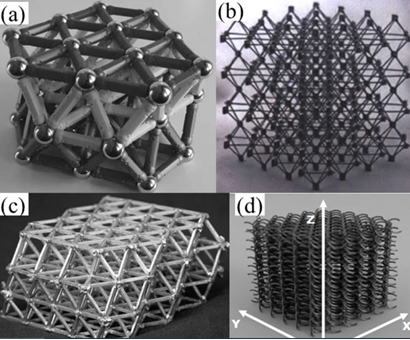

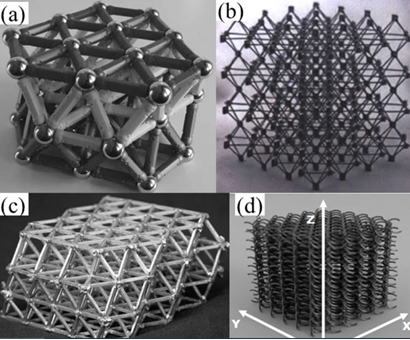

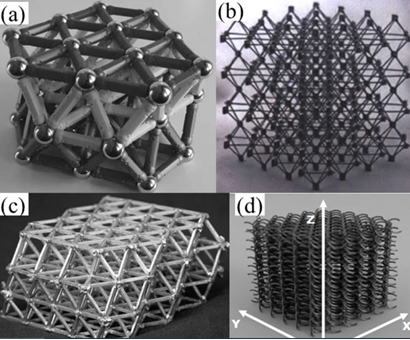

Lattice structures, which are also known as architected cellular structures, have been applied in various industrial sectors, owing to their fascinated performances, such as adoptable elastic modulus, high stiffness-to-weight ratio, low thermal expansion coefficient, and large specific surface area [1]. The lattice structures fabricated by conventional manufacturing technologies always involve complicated process control, additional assembly steps, or other uncontrollable factors. Furthermore, limited types of unit cells can be used to construct lattice structures when using conventional processes.

Fortunately, additive manufacturing technology, based on a layer-by-layer process from computer-aided design models, demonstrates the unique capability and flexibility and provides an ideal platform in manufacturing complex components like lattice structures, resulting in an effective reduction in the processing time to actual application and minimum of material waste. Therefore, additive manufacturing relieves the constraint of structure design and provides accurate fabrication for lattice structures with good quality. There is a need for more research on the design, optimization, a variety of properties, and applications of metallic lattice structures produced by additive manufacturing [1].

Requirements:

- The work is in collaboration with the international partners. The supervision of the work will be primary conducted remotely and online.

- Given the international nature of the project, the language of the work (including presentations and report) will be in English.

- A master thesis (Masterarbeit) is preferred for this topic

Reference

- [1] L.-Y. Chen, S.-X. Liang, Y. Liu, L.-C. Zhang, „Additive manufacturing of metallic lattice structures: Unconstrained design, accurate fabrication, fascinated performances, and challenges” Materials Science and Engineering: R: Reports, vol. 146, 100648, 2021

- [2] B. Khoda, A.M.M. Nazmul Ahsan, A.N. Shovon, A.I. Alam “3D metal lattice structure manufacturing with continuous rods” Scientific Reports 11, 434, 2021

30167 Hannover