Metal 3D-Printing for Construction

International Collaborative Project

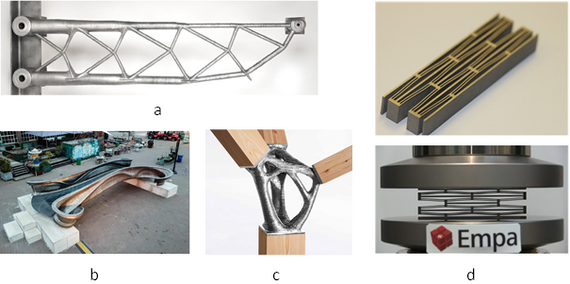

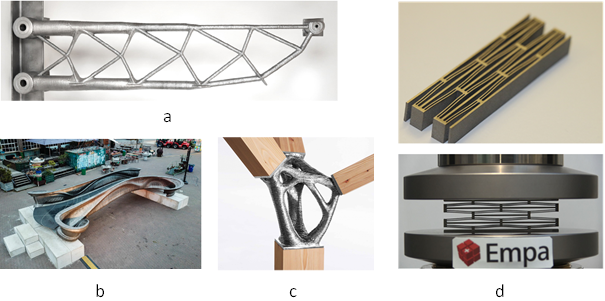

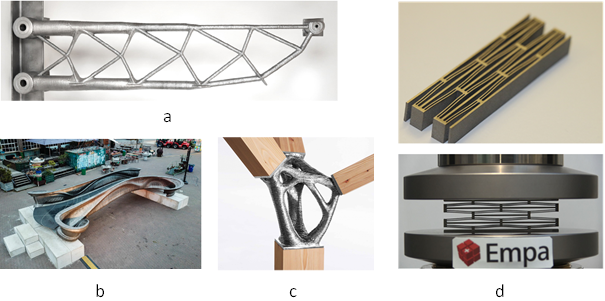

Metal additive manufacturing is one of the technologies that opens up new possibilities for construction of steel structures, including but not limited to lightweight structures with non-prismatic sections, complex connections, internal stiffening, functionally graded elements, lattice structures, repair and strengthening of existing structures, variable microstructure and material properties. Geometrical freedom of additive manufacturing not only allows us to enhance material utilisation with optimisation strategies, but also enable us to design and incorporate innovative functionalities in the structure. Theoretical development and practical application of computational and simulation tools for additive manufacturing are still widely required.

Various challenges such as design methodology, parametric design/optimization, characterization of mechanical and geometrical properties of 3D-printed components, verification and standardization, sustainability assessment and cost are in need of further investigation [1].

Requirements:

- The work is in collaboration with international partners. The supervision of the work will be primarily conducted remotely and online.

- Given the international nature of the project, the language of the work (including presentations and report) will be in English.

- A master thesis (Masterarbeit) is preferred for this topic.

References

- [1] C. Buchanan and L. Gardner, "Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges," Engineering Structures, vol. 180, pp. 332-348, 2019.

- [2] J. Ye, P. Kyvelou, F. Gilardi, H. Lu, M. Gilbert, and L. Gardner, "An end-to-end framework for the additive manufacture of optimized tubular structures," IEEE Access, vol. 9, pp. 165476-165489, 2021.

- [3] Mx3d.com

- [4] Sustainable Metallic Structures Group (SUMS), Structural Engineering Laboratory, Empa, Switzerland.

30167 Hannover